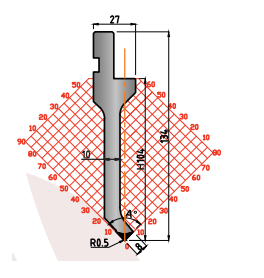

The Standard Semi Gooseneck Punch (ASG-1002) is designed for precision metal bending applications in press brake operations. The semi-gooseneck design offers additional clearance, making it ideal for bending complex shapes while maintaining high structural integrity. This punch ensures accurate, repeatable bends and is built to withstand up to 50 T/m of pressure, making it suitable for light to medium-duty forming tasks.

A semi-gooseneck punch provides extra clearance for bending operations involving return flanges and deep bends while maintaining durability and precision.

Yes, it is compatible with most standard press brakes but may require adapters for specific machine configurations.

Yes, customizations such as different heights, angles, and radii can be made based on specific bending requirements.

Available through industrial tooling suppliers, press brake manufacturers, and authorized dealers.