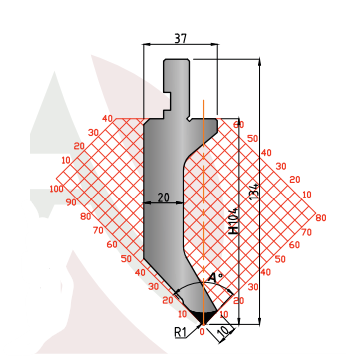

The Standard Full Gooseneck Punch (AFG-1002) is a high-precision press brake tool designed for deep bends, return flanges, and complex part formations. Its full gooseneck design provides maximum clearance, preventing material interference while maintaining strength and durability. Engineered for precision and efficiency, this punch ensures accurate and repeatable bending performance in heavy-duty applications.

A full gooseneck punch is a specialized press brake tool designed to allow for deeper bends and return flanges without interfering with the material being formed.

Yes, it is compatible with most standard press brakes, but some machines may require adapters for installation.

Yes, custom heights, angles, and radius options can be manufactured based on specific bending requirements.

Available through industrial tooling suppliers, press brake manufacturers, and authorized dealers.